Handset

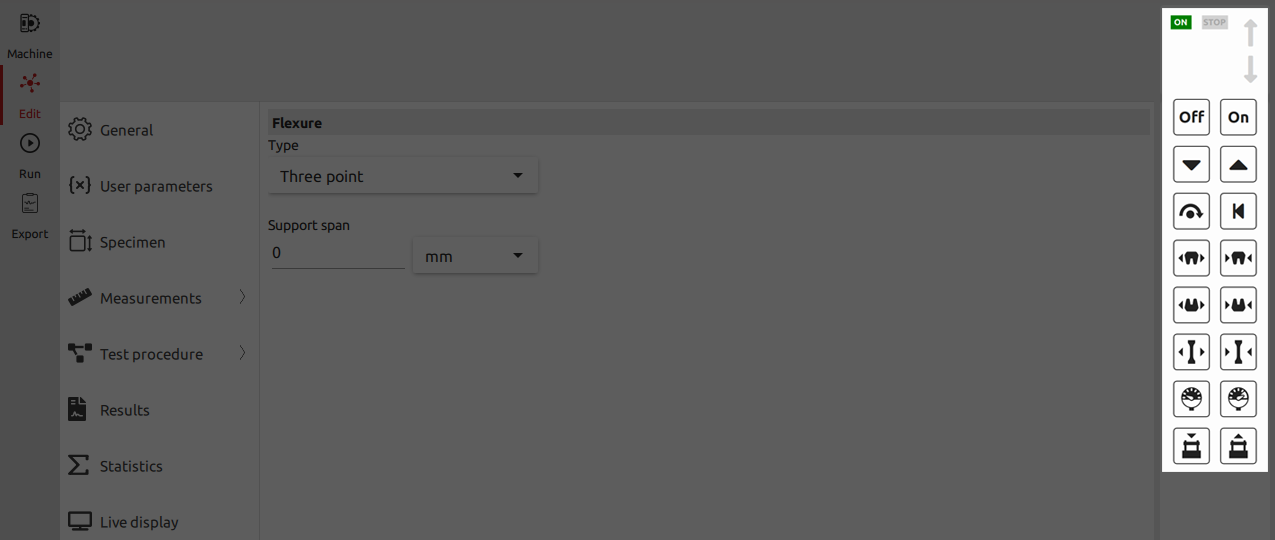

The handset controller is an intuitive interface designed to facilitate seamless interaction with the material testing application. Its compact form factor houses a small, informative display that provides real-time status updates regarding the connected device.

You can hide the handset bar by clicking on the layout button.

Featuring intuitive arrow controls, the handset enables precise manipulation of grips and other test settings, offering users a convenient means to adjust parameters and monitor the ongoing test process. Its ergonomic design ensures user comfort during prolonged usage.

Compact Display

Offers clear visual feedback on the status of the connected device and ongoing device status.

The display prominently showcases the following critical information:

- On/Off Status: Clearly indicates the current operation status of the connected device, ensuring easy visibility of its operational state.

- Emergency Stop Alert: Instantly notifies users in case of an emergency stop, limit switches... prioritizing safety measures during machine movemnet.

- Crosshead Movement Direction: Displays intuitive arrow indicators indicating the movement direction of crosshead, whether moving up or down.

The ergonomic design and clear, concise display make the handheld controller an indispensable tool, offering immediate insights and control over key functionalities during material testing operations.

Buttons set

The buttons provide convenient operation for the following functions:

- On/Off Control: Enables effortless power management, allowing users to toggle the device on or off swiftly.

- Crosshead Movement Control: This control mechanism allows users to dictate the displacement or position of the crosshead during the testing process. It involves specifying how the crosshead should move, at what speed or rate, and in which direction. Precise control over the crosshead movement is essential for conducting accurate and reliable material tests, as it influences parameters such as deformation, strain, and elongation of the specimen. The control may be achieved manually or through automated systems, providing flexibility and precision in the testing procedures.

- Bypass Valve Control(for hydraulic systems): Bypass Valve Control in hydraulic systems involves the strategic manipulation of a bypass valve to regulate the flow of hydraulic fluid. This control mechanism, whether manual or automated, enables operators to adjust flow rates and maintain optimal pressure levels within the system. By actively managing the bypass valve, the hydraulic system can enhance efficiency, control the speed and force of hydraulic actuators, and protect against overpressure, ensuring the safe and effective operation of machinery in various industrial applications.

- Return to Initial: typically refers to a command or action in a system or application that instructs it to revert to its initial or default state. In various contexts, such as software interfaces or control systems, selecting "Return to Initial" would prompt the system to reset or go back to the original configuration or settings.

- Grip Movement Control: Facilitates directional adjustments for Extensometer, offering options to move them left, right, up, or down with precision, ensuring optimal positioning for testing procedures.

- Extensometer Arm Control (open/close): Offers control over the Extensometer's position, allowing smooth movement inwards or outwards for precise placement within the testing apparatus.

- Low/High Pressure (for hydraulic systems):

Hydraulic systems use pressurized fluid to transmit power, and maintaining appropriate pressure levels is crucial for their proper functioning.

-

Low Pressure: This typically signifies the lower end of the pressure range within the hydraulic system. Low pressure may be required for specific tasks or phases of operation, such as during system startup or when less force is needed.

-

High Pressure: On the other hand, high pressure indicates the upper range of pressure that the hydraulic system can generate. High pressure is often necessary for tasks requiring more force, such as lifting heavy loads or performing intense mechanical work.

Control over low and high-pressure settings is essential for optimizing the performance and efficiency of hydraulic systems. It involves the use of pressure control valves, regulators, and sensors to maintain pressure within desired limits. Proper pressure management ensures that hydraulic components operate effectively, prevents damage due to excessive pressure, and contributes to the overall safety and reliability of the hydraulic system.

- Fixed Frame Movement Control: "Fixed Frame Movement Control" pertains to the regulation and management of the movement of a fixed frame in mechanical or material testing systems. The fixed frame is a stable component that provides a reference point for the testing apparatus. This control mechanism allows users to dictate the displacement, position, or stability of the fixed frame during testing procedures. The precise control over fixed frame movement is crucial for conducting accurate and reliable material tests, influencing parameters such as specimen positioning and overall testing stability. Control may be achieved manually or through automated systems, providing users with flexibility and precision in their testing processes.